Air plasma cutting remains one of the most accessible and pragmatic technologies in metalworking. Designed for workshops, fabrication units, repair services and industrial maintenance teams, air plasma cutters deliver fast, precise cuts across multiple metals with minimal setup requirements. Because they use compressed air instead of mixed gases, they offer lower operating costs and simpler daily use, making them a strategic asset for businesses that need reliable cutting without the complexity of a full CNC or multi-gas system.

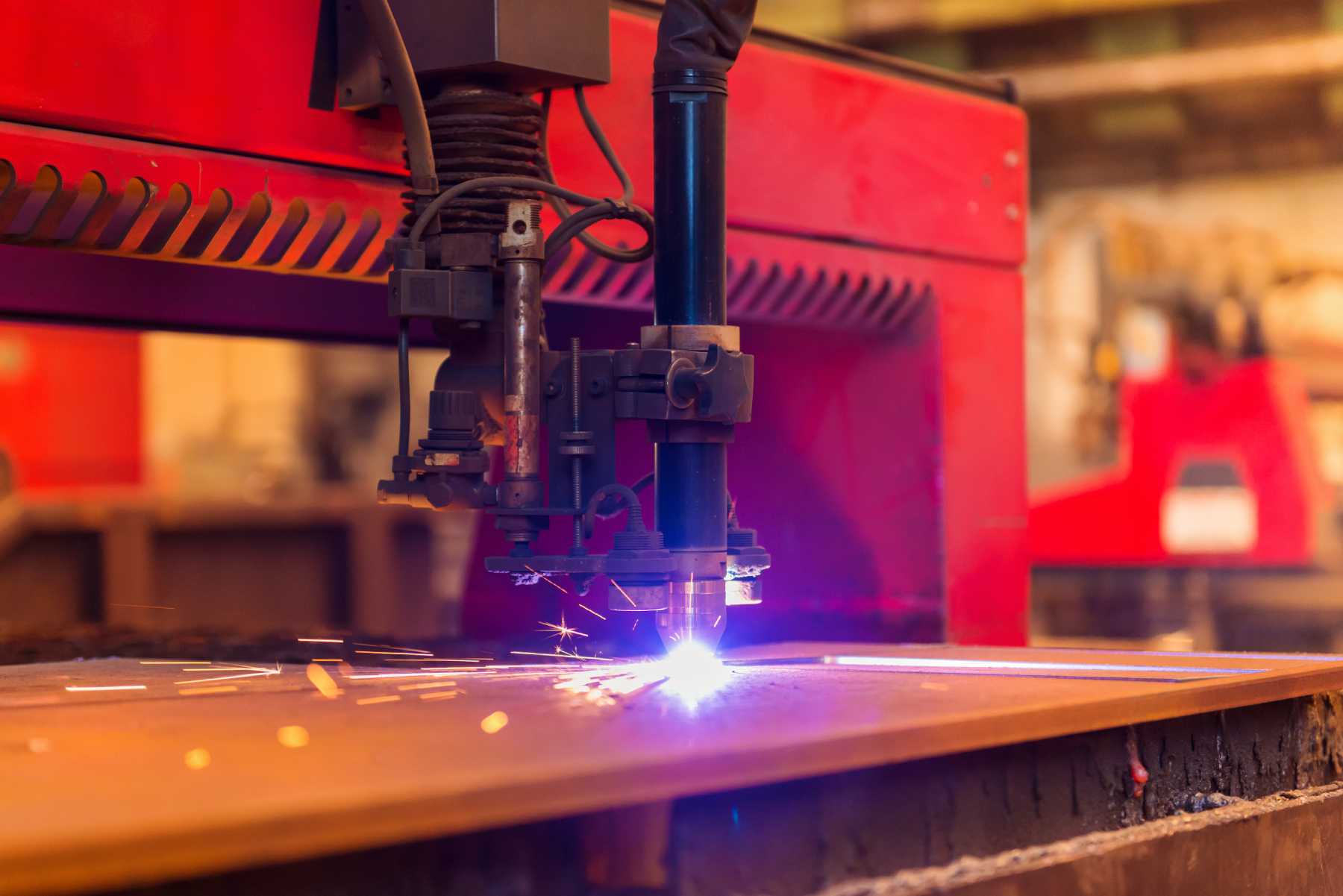

Plasma technology works by ionising compressed air into a high-temperature plasma arc capable of melting and expelling metal with high speed. This process provides clean, narrow kerfs and strong accuracy for general fabrication tasks. Air plasma cutters do not aim to replace high-power fiber lasers or heavy industrial CNC plasma systems — instead, they fill a critical operational gap: fast, efficient, flexible metal cutting where mobility, cost efficiency and ease of deployment matter.

Key advantages of air plasma cutting

Air plasma cutters offer a balance of performance and cost that suits a wide range of industries:

- Multi-metal capability

Steel, stainless steel, aluminum and other conductive metals can be cut quickly, making air plasma ideal for workshops handling mixed materials.

- Lower operating costs

Compressed air replaces expensive oxygen or gas mixtures, reducing consumable expenses and simplifying logistics.

- Portable and shop-friendly

Compact form factors, integrated compressors in some models, and straightforward controls allow use on shop floors, field repairs or mobile maintenance operations.

- Strong performance for general fabrication

For tasks like bracket cutting, sheet preparation, structural modifications, repair jobs, automotive work, agricultural equipment servicing and custom metal fabrication, air plasma delivers the required precision without the overhead of larger systems.

- Better cut quality than mechanical tools

Compared to grinders, saws or oxy-fuel on thin metals, air plasma offers cleaner edges, reduced heat distortion and faster execution.

Industrial applications

Air plasma cutters integrate efficiently across multiple verticals:

Fabrication and welding shops

Operators can cut sheet metal, beams, tubes and brackets before welding operations. Fast preparation improves throughput and reduces manual grinding.

Maintenance, repair & operations (MRO)

From machinery repairs to on-site adjustments, air plasma cutters offer mobility and immediate readiness — essential in industrial plants, construction sites and service fleets.

Automotive and bodywork

Cutting through frames, panels and supports is significantly easier with plasma’s clean, controlled arc.

Agricultural and construction equipment repair

Field repairs benefit from air plasma’s ability to cut heavy steel parts without specialised gases.

Metal artisans & custom manufacturing

Small craft shops rely on air plasma for prototyping, decorative metalwork and quick custom cuts.

Why workshops choose air plasma over oxy-fuel

While oxy-fuel remains dominant in thick steel cutting, air plasma is preferred for:

- thinner materials

- stainless steel and aluminum

- faster production without pre-heating

- cleaner edges on general workshop tasks

- lower consumable and gas management requirements

For companies that do not need the full automation of a CNC system, air plasma provides a high-value, compact solution that supports daily production efficiently.

Choosing a machine

When selecting an air plasma cutter, workshops typically evaluate:

- current output (amps) for maximum thickness capacity

- duty cycle for continuous industrial use

- integrated vs external compressor

- torch quality and consumable availability

- pilot arc functionality for cutting painted or rusty surfaces

- safety and cooling systems

These variables ensure the machine matches the intended operational workload and supports stable, long-term use in demanding environments.

Conclusion

Air plasma cutters deliver an optimal blend of mobility, efficiency and multi-material capability, making them indispensable for metalworking environments that require fast and flexible cutting. They are cost-effective, user-friendly and powerful enough to handle most workshop and industrial tasks — from fabrication and repair to field modifications and custom builds.

As part of a broader production ecosystem, they complement CNC plasma, laser and oxy-fuel systems by covering everyday cutting needs quickly and economically.